How nature-inspired ultrasonic sensor technology has evolved so we can build safer autonomous vehicles in today’s Industry 4.0!

Reading Time: 4 Minutes approx. – 20/01/2022

With over 3,8 billion years of rigorous R&D, Nature is by far the most sophisticated and powerful innovator there is. Painstakingly observing and studying nature’s marvels, we humans have been able to develop innovative technologies, such as utilising the shape of birds in the design of aircrafts to make them fly or using injection needles inspired by mosquitos. Another example is using ultrasonic echolocation technology by studying the way bats use echolocation to hunt for prey. We are taking echolocation to a next level by building the world’s first 3D Ultrasonic Echolocation Sensor. With its proprietary sensing and detecting technology, it enables next-level safety for industrial robotic and automotive applications.

This article will provide fascinating insights into how ultrasonic technology has evolved to the present state-of-the-art 3D sensing technology we build today. To add a third dimension to ultrasonic sensing is especially important, as 3D ultrasonic sensors can detect the most complex objects in 3D space regardless of unfavorable lighting conditions. This improves overall operational efficiency, reduces accidental costs, and enables the safe use of AGVs in any working condition.

Ultrasound in Nature

Whether it’s a gigantic blue whale or the smallest insect on the planet, nature has found an innovative solution to support the survival of all life forms. As aforementioned, humans have long started to adopted nature’s amazing biological principles to improve all parts of live. This is commonly referred to as “bionics” – a combination of the words “bios” (Greek for “life”) and electronics, which covers the study of electronic systems which function to the same principles as organic systems. As humans, this is what makes us unique as a species that can observe, learn, and build unique technologies.

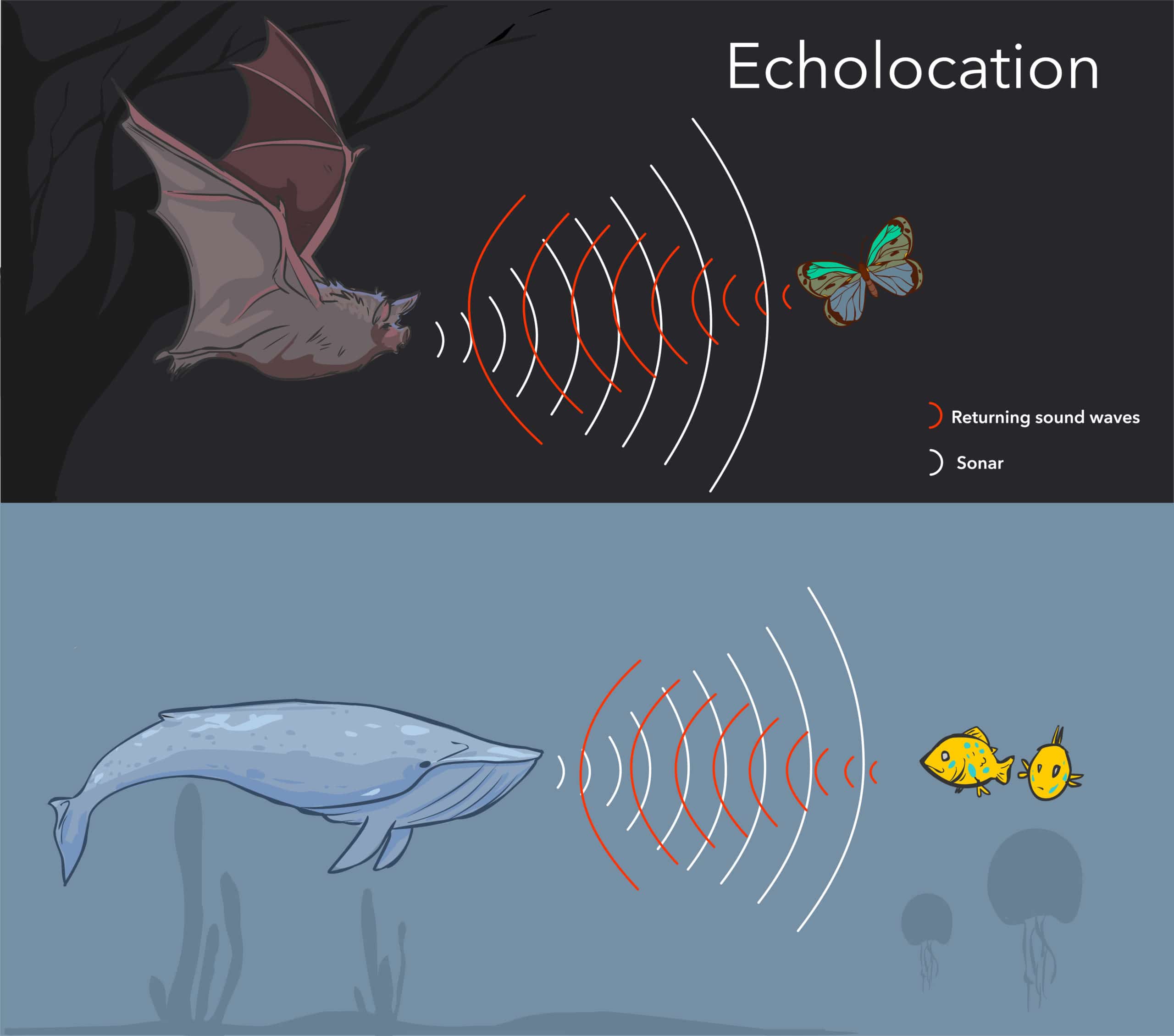

Similarly, we observed that ultrasound waves, which travel at frequencies above the audible spectrum for humans (around 20 kilohertz or kHz), are effectively used by many species in nature such as bats, dolphins and whales in their everyday activities.

The first evidence of animals using sound was observed by Italian biologist Lazzaro Spallanzani in 1794, when he performed studies on bats which concluded that bats could navigate using sound rather than sight. They emit sound waves from their nose or mouth and when the waves hit an object, an echo is produced. This echo is reflected to the bats’ ears. Bats can then interpret the echoes to determine the size, location, and shape of the object. This is known as echolocation. Bat echolocation sounds range from 9 kHz to 200 kHz. Like bats, dolphins and whales also use echolocation to navigate, communicate, and hunt in the deep, dark, and murky waters.

Development of Ultrasonic Technology

Over the past 225+ years, we are experiencing the development and evolution of technologies in any kind of industry – so when did ultrasonic sensing have its debut? In 1914, Reginald A. Fessenden built the first working system in the United States which could detect icebergs two miles away, for instance. Today, ultrasonic technology is used in various applications in other areas such as military, medical, and manufacturing. With its technique of echo-reflection, many advanced medical devices were built as early as the 1960s to detect tumors, as well as for overall body scanning and cardiac-related diagnosis.

In the modern era, ultrasonic technology is used in many different industrial applications, measuring distances, parking assistance, flow-rate measurement, level detection, and composition analysis.

The latest technological advancements such as smart machines and the Internet of Things (IoT) have paved the way for the most recent applications of ultrasonic sensors: as an object detection and ranging device implemented into automated vehicles for guidance purposes. The automation process of Industry 4.0 and especially Intralogistics 4.0 has seen the advent of unmanned vehicles, so-called Automated Guided Vehicles (short AGVs). Today, with the e-commerce market booming, the global AGV market is expected to grow from 5.21 billion (in 2019) to 13.52 billion (by 2027) with a projected CAGR of 16.6% from 2020 to 2027. This demonstrates the continued importance AGVs not only play today but will do so for the foreseeable.

Ultrasonic sensors are a key component used in the automation of these self-driving robots especially so as they are crucial for warehouse safety: they help improve the efficiency of AGVs and decrease overall operating costs, as we’ll describe below.

State-of-the-Art 3D Ultrasonic Sensors at Toposens

Today, there are various sensing technologies for object detection in place, such as cameras, RADAR, LiDAR, and 1D ultrasonic sensors (SONAR). LiDAR and camera sensors detect and range by way of light, whilst ultrasonic sensors use sound waves and RADAR sensors radio waves. The performance of these technologies depends heavily on the physical properties on which they are based. Sensing can be negatively impacted by unfavorable light conditions, reflections, and weather, limiting the overall efficiency of optical sensors such as LiDAR and cameras. Due to these performance impediments, AGV-related accidents amount to 100,000 USD plus in damages per factory per year. Hence, warehouse safety and automation are crucial to improving efficiency and decreasing operating costs.

Going back to our masters of natural night-vision: Up to now, no one has ever achieved to copy the bat’s echolocation prowess, detecting multiple obstacles in real-time and in 3D space. Through many years of research, Toposens has successfully managed to create an unprecedented technological breakthrough by developing the world’s first 3D Ultrasonic Sensor, based on the principle of bionics, mimicking said echolocation techniques.

Just like bats, Toposens ECHO ONE® 3D ultrasonic sensors can detect multiple objects in real-time using sophisticated software, which subsequently delivers robust, light tolerant, low cost, and precise, near-range data output in a point cloud on x, y, and z (3D) coordinates. This enables the reliable detection of even complex objects such as forklift forks. These are often not detected reliably enough by e.g. 2D LiDARS, which are delivering x and y coordinates, yet no z (= vertical position) coordinate.

As we know, bats are wild animals living in the great outdoors, hunting down prey through echolocation in all sorts of (un-) favorable weather and light conditions. We mimic this technology in an electronic sensing system, the ‘ECHO ONE® System’, which can detect and range in all sorts of weather and light conditions in true bat vision style (except for the hunting bit). This is due to its patented, IP67-certified design and sensing capabilities.

Besides, it reduces overall operating costs as one of our sensors will be enough to cover a large Field-of-View. This is due to the ultra-wide opening angle of up to 180 degrees in ultra-short range, providing a much larger Field-of-View (FoV) than other sensors. This in turn increases productivity, reduces accidents, and most importantly increases safety.

So just like bats have evolved to perfect their echolocation techniques, our sensor technology has evolved over time and is now at a stage where it provides next-level robotic safety for AGVs and similar robots, adding another element of vision to their safe and reliable guidance.

For more information on the various sensor types used in today’s autonomous industries, read our previous blog article covering the topic of sensor fusion for reliable collision avoidance.

To learn more, visit www.toposens.com.

For specific enquiries about our unique 3D ultrasonic sensor system and its applications, please get in touch with our experts.

About MEYSENS GmbH

MEYSENS GmbH was founded in early 2023 out of Toposens GmbH (est. 2015) and is made up of experts in embedded systems, hardware development, 3D sensing, digital signal processing, and machine vision. Together, we have successfully developed the worlds-first 3D Ultrasonic Sensor “Toposens ECHO ONE®” based on the principle of bionic, mimicking the echolocation techniques of a bat, to deliver robust, low-cost, and precise near-range 3D data points. Unlike existing sensor technologies, which can be negatively impacted by light conditions, reflections, and weather, our system uses real-time 3D data mapping and object recognition software to guide autonomous systems such as AGVs, even in the most difficult environments.