FAQs

Find answers to your most common questions relating to our technology.

Frequently Asked Questions

General

Technology

Application

General

Technology

Application

Below you will find a selection of the most common questions we get asked. By clicking on the above tiles, you can take a look at the three categories:

General – Technology – Application

Should you have a querie which is not listed below, please feel free to contact us via support@toposens.com and we will get back to you with feedback and include it in our FAQs.

General

1. What is the Toposens 3D Collision Avoidance System?

The Toposens ECHO ONE 3D Collision Avoidance System (short: ECHO ONE 3DCAS) is an ultrasound-based system providing collision avoidance functionality to mobile robots. It has two main components: a sensor that provides a 3D point cloud and a Processing Unit (TPU) which processes the point cloud to deliver high-quality information about impending collisions.

2. What is ultrasound and how is it used for 3D location of objects?

Ultrasound refers to sound waves with a frequency higher than is detectable by the human ear. Our sensors send out ultrasonic pulses with a frequency of approx. 40 KHz. and, upon reflection off an object, receive the echoes via tiny microphones built into the sensor (typically a single strong reflection per object, though this varies depending on the object’s shape). By measuring the time between wave emission and wave reception, the distance to the object can be calculated. This principle is called Time-of-Flight (ToF) measurement.

ToF is calculated using the following formula: D (distance) = T (time) x V (velocity of speed of sound in air = 343 m/s) / 2

3. What product portfolio does Toposens offer?

3D Collision Avoidance System:

Includes our 3D Ultrasonic Echolocation Sensor ECHO ONE® and the Toposens Processing Unit (TPU) to utilize the full capacity of our 3D collision avoidance functionality in your running operations.

Products:

Toposens ECHO ONE®: Toposens 3D Ultrasonic Echolocation Sensor ECHO ONE®

TPU: Toposens Processing Unit (TPU)

4. How does the Toposens ECHO ONE® compare with LiDAR?

LiDAR sensors have difficulties in detecting small or transparent objects, especially at ground level. Additionally, LiDARs have a “dead zone” in the region immediately close to the sensor. The ECHO ONE® detects objects from 20 cm distance (even closer when using the near field detection) and can detect both extremely small and transparent objects up to a range of 3 m. Due to a sparser point cloud, the ECHO ONE® requires much less data processing, offering a much lower power consumption, which in turn increases your ROI.

5. How does the Toposens ECHO ONE® compare with 3D cameras?

3D cameras are very sensitive to light and environmental conditions and require complex data processing software. The ECHO ONE® is mostly insensitive to direct sunlight and to outdoor weather conditions (dust, fog, rain, snow).

6. How does the Toposens ECHO ONE® compare with 3D radar?

3D ultrasonic technology is at its core similar to 3D radar in that both are based on waves, with 3D radar being based on electromagnetic waves not ultrasonic waves. 3D radar tends to be error-prone to non-metallic materials like wood and plastic. The ECHO ONE® can detect objects regardless of their material and is more cost-effective.

7. How does the Toposens ECHO ONE® compare to typical 1D ultrasonic sensors?

A typical 1D ultrasonic sensor will only provide distance measurements, i. e. the distance to the nearest object relative to a sensor with a very limited Field-of-View. Besides providing simple distance measurements, our sensors provide the position of the object in 3D space, relative to the sensor. Additionally, our technology has a Field-of-View up to 120°.

8. How can I buy the Toposens 3D Collision Avoidance System?

Please get in contact with us at sales@toposens.com.

9. Which countries do you ship to and how long is the delivery time?

We ship our products worldwide. Delivery times vary between 3 and 4 weeks upon receival of the purchase order.

10. Is the Toposens 3D Collision Avoidance System certified? Does it have a safety rating?

The ECHO ONE® sensor is IP67 certified, meaning it is completely dust proof and can be temporarily submerged in water, making it an ideal sensor to be used in outdoor applications even during unfavourable weather conditions. Both the sensor and the TPU comply with the guidelines CE, FCC and RoHS. The System ist not rated for Functional Safety.

11. I cannot login into the Member’s Area, what should I do?

Please get in contact with us at support@toposens.com.

12. Does the ECHO ONE® perform object classification?

No. Neither the ECHO ONE® sensor nor the TPU provide any object classification.

Back to top ↑

Technology

1. How small are the objects detected by the Toposens 3D Collision Avoidance System?

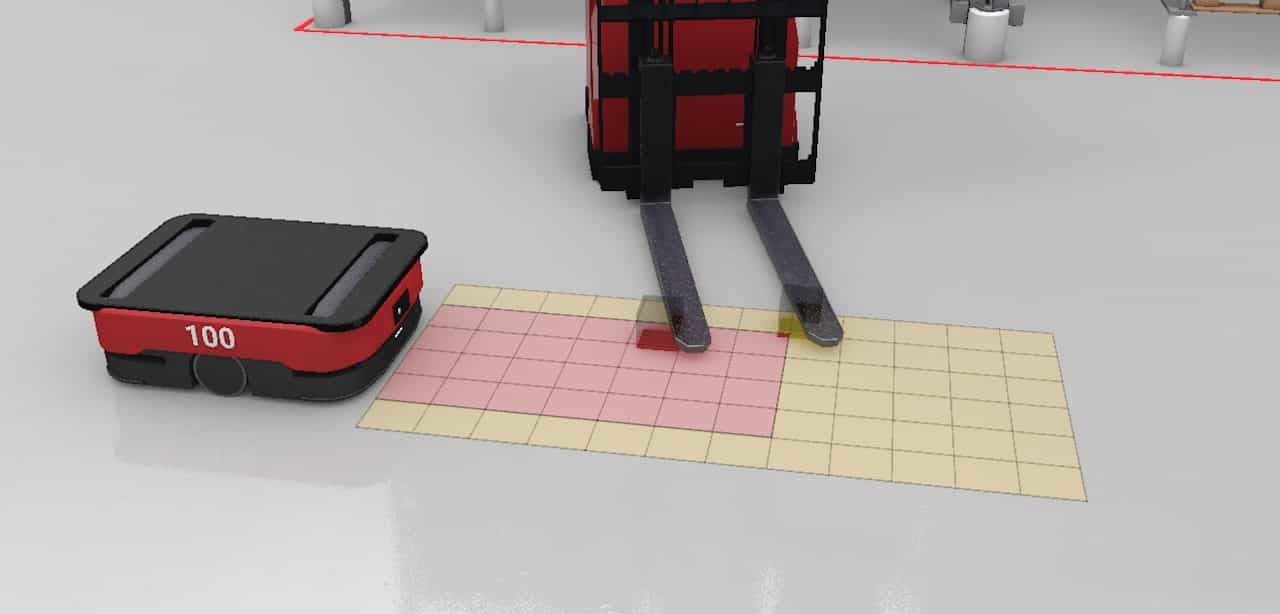

The ECHO ONE can be configured to detect objects of different sizes. The smallest objects that can be detected at a range of 1 meter are approximately 40x20x5 mm in volume. Typical objects that can be detected are power cables, cable ducts and even the tips of forklift forks.

2. Can I use the data provided by Toposens 3D Collision Avoidance System to perform Sensor Fusion?

You can receive the processed point cloud data from the Toposens Processing Unit (TPU). The TPU additionally provides signal flags to indicate violations of the warning and stopping zones.

3. How can Toposens 3D Collision Avoidance System system help my mobile robot avoiding collisions?

Once you have integrated the Toposens ECHO ONE 3D Collision Avoidance System into your mobile robot and configured it, the TPU will output zone violation signals (depending on which zone is violated), to either slow down (due to violation of warning zone) or completely stop (due to violation of stopping zone) your mobile robot before a collision happens.

4. Does the Toposens 3D Collision Avoidance System provide a point cloud similar to the ones provided by LiDAR sensors?

Because our technology works with sound waves, the point cloud is sparser than the one obtained from a LiDAR. You can see typical ECHO ONE® sensor point clouds in this video.

5. How sensitive is the ECHO ONE® sensor to velocity?

The Doppler effect caused by motion only becomes relevant for very high speeds and in practical cases does not affect the performance of the ECHO ONE® . The recommended maximum AGV speed is about 5.7 km/h (1.6 m/s). At relative speeds higher than 15 km/h (4.2 m/s) the data becomes unreliable and at higher speeds, the sound of wind may cause significant noise in the point cloud.

6. What is the operating range, Field-of-View and resolution of the ECHO ONE®?

The ECHO ONE® has an operating range of up to 3 m with a Field-of-View of up to +- 60° in ultrashort range (from 10 cm to 100 cm) and +-55° from 1 m up to 3 m, depending on parameter setting.

7. Can I communicate directly with the ECHO ONE® sensor or do I need the Toposens Processing Unit (TPU)?

We recommend that you communicate with the TPU so that you can use the filters to get a higher-quality point cloud and to get information about zone violations.

8. Can noise interfere with the performance of the ECHO ONE® and if so, what type of noises interfere mostly?

If a source of noise is very intense and has frequencies around 40 KHz., it may jam the ECHO ONE® signals. Tools which typically emit ultrasound in the same frequency range as the ECHO ONE® are air pressure pistols, welding tools and plasma cutters. As a rule of thumb, the system is able to deal with a noise source in >1m distance at a maximum of 100dB.

9. Can one ECHO ONE® sensor interfere with another?

The ECHO ONE® sensors have a special operating mode called Medium Monitoring Mode (MMM), allowing them to detect and synchronise with one other, thus avoiding interferences.

10. How many ECHO ONE® sensors can I connect to a single TPU?

Currently you can connect one ECHO ONE® sensor per TPU. We will soon provide a firmware update to our customers to allow connecting several sensors (up to 4) to one single TPU.

11. What kind of information does the ECHO ONE® provide for each point within the point cloud?

Each point in the point cloud is characterized by five values: three coordinates in space (X, Y, Z), a confidence value (indicating how close the received shape of the echo is to the expected signal shape), and an intensity value (intensity of the echo received).

12. Which frame rate does the Toposens 3D Collision Avoidance System provide points with?

Our system provides point clouds at 20Hz.

13. Which communication protocols does the Toposens 3D Collision Avoidance System use and which interfaces can I use to receive the data?

We provide the filtered point cloud from the TPU via UDP/Ethernet. Additionally, the TPU also provides digital output pins to indicate configured warning and stopping zones have been violated by any object.

Back to top ↑

Application

1. For which kind of applications is the ECHO ONE®?

The ECHO ONE® is intended for 3D collision avoidance applications. It can be configured to detect both very small and larger objects, on the floor or at height. You can use this capability to:

reduce the downtime of mobile robots in logistic operations

reduce costs arising due to accidents during operation

reduce manufacturing & running costs of a mobile robot due to fewer sensors required

2. How many ECHO ONE® sensors do I need for my mobile robot?

That really depends on the capabilities and size of your mobile robot. Please get in contact with us at support@toposens.com.

3. Is there any limitation to the number of ECHO ONE® sensors active in the same area?

For practical reasons we recommend a maximum number of three sensors active simultaneously in a radius of 10m.

4. Is it possible to perform 3D mapping with the ECHO ONE®?

For 3D mapping you need odometry data, which the ECHO ONE® does not provide. You can use the ECHO ONE® for 3D mapping if you couple it with other sensors in a sensor fusion system.

5. Is there a minimum required height for an integration of the ECHO ONE® into a mobile robot?

If you still want to use near field detection, we recommend a minimal mounting height of 20cm, though lower is also possible. For optimum performance, we recommend a mounting height <40cm.

6. How easy is it to use the Toposens 3D Collision Avoidance System? Is any training needed to fully understand and utilise the software?

We provide you with an instruction manual for the Toposens ECHO ONE® 3D Collision Avoidance System, and an application manual to help you run the system.

7. Can I communicate with the Toposens 3D Collision Avoidance System using Windows and Linux?

You can connect to the TPU using both Window and Linux OS. You can connect directly to the sensor using Linux system.

8. I don’t understand how to use the Toposens Collision Avoidance System, what should I do?

Please get in contact with us at support@toposens.com.

Back to top ↑