ECHO ONE®

Toposens Next-Generation 3D Ultrasonic Sensing Technology

Meet us at Sensor + Test 2024

11 – 13 Juni 2024

Messe Nürnberg

Booth: 1 – 120

Meet us at LogiMAT 2024

19 – 21 March 2024

Messe Stuttgart

Booth: 8D 53

Precision

| Safety

| Easy Integration

Precision

| Safety

| Easy Integration

ROS

Package

from 10 mm

Operating Range

~20Hz

Frame Rate

up to 140°

Opening Angle

IP67

Certified

CAN

Communication Interface

+/- 6 cm

Typical

Accuracy

up to 3 m

3D Detection Range

~20 Hz

Frame Rate

up to 140 °

Opening Angle

IP67

Certified

200 ms

Response Time

Ethernet or Digital I/O

Communication Interface

Why use 3D Ultrasonic Sensors?

Need for 3D Collision Avoidance

Necessity of Reliable Operations

Best-In-Class 3D Detection

Detecting the Undetectable

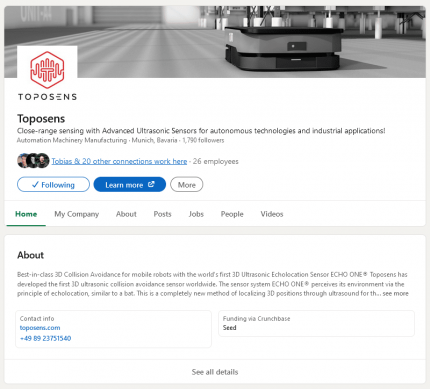

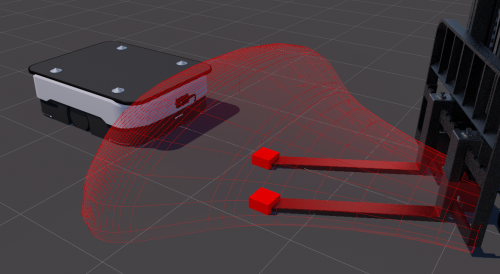

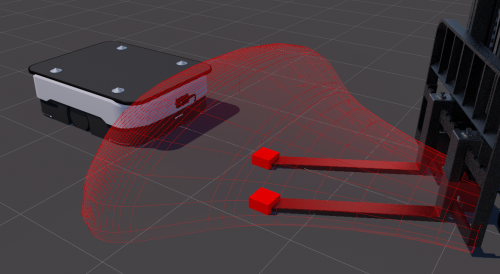

The 3D Echolocation Sensor Toposens ECHO ONE® enables your mobile robot to reliably detect even the most complex objects in three-dimensional space, such as forklift forks, floor-based objects, and even glass. With a small blind zone, ultra-wide opening angle, and detection range of up to 3 m, you can reduce costly accidents whilst ensuring highest safety in any environment.

Based on our proprietary 3D ultrasonic technology, our ultrasonic sensors use Time-of-Flight echolocation data for detection in three-dimensional space, filtered by the Toposens Processing Unit for 3D collision avoidance, offering you next-level robotic safety.

Plug and Play Solution

Unprecedented 3D Collision Avoidance for your mobile robot, made possible with the combination of Toposens ECHO ONE® and Toposens Processing Unit.

The system equips your mobile robot with best-in-class 3D collision avoidance to detect all kinds of obstacles reliably, so you can build and use the safest mobile robots in the market. It consists of the next generation 3D Ultrasonic Echolocation Sensor ECHO ONE® and the Toposens Processing Unit (TPU), providing reliable data filtering and 3D collision avoidance funtionality

ECHO ONE®

Toposens Processing Unit

3D Collision Avoidance

The convenient gateway between ECHO ONE® and your robot.

The Toposens Processing Unit (TPU) serves the need of easy integration of the Toposens 3D ultrasonic sensing technology for 3D collision avoidance. It enables customers to use pre-filtered point clouds displayable in a Graphical User Interface (GUI) to make use of the 3D collision avoidance functionality by setting dynamical three-dimensional, adjustable warning- and stopping-zones.

Along with the next-generation 3D Ultrasonic Echolocation Sensor ECHO ONE®, the system enables your AGV, robot, or other application to avoid collisions with all kinds of obstacles.

Advanced 3D Collision Avoidance Functionality

Plug & Play Hardware with Different Interfaces

Easy-to-use Software for Application Setup

3D Collision Avoidance System

Watch the below YouTube video to find out how the 3D Ultrasonic Echolocation Sensor Toposens ECHO ONE® and the Toposens Processing Unit are working together to provide your robot with next-level robotic safety.

6 Unique Benefits of the ECHO ONE®

We know your pain and can help you increase your profitability and reduce costly accidents.

Find out how:

Simply click on the text below to find out about our six unique advantages of 3D Ultrasonic sensing.

Is your AGV or similar robot not performing to the highest standards because the implemented sensor technology can only detect the nearest object?

Traditional 1D Time-of-Flight sensors can detect only the closest object relative to the sensor. Due to our unique hardware setup and advanced algorithms-based software technology, our sensor can detect multiple objects in 3D space in real-time. This reduces accidents, optimizes your factory workflow, and improves your operational efficiency.

Is your AGV or similar robot not performing to the highest standards because the implemented sensor technology can only detect the nearest object?

Traditional 1D Time-of-Flight sensors can detect only the closest object relative to the sensor. Due to our unique hardware setup and advanced algorithms-based software technology, our sensor can detect multiple objects in 3D space in real-time. This reduces accidents, optimizes your factory workflow, and improves your operational efficiency.

Are you tired of tedious integration procedures?

The Toposens Processing Unit (TPU) serves the need of easy integration of the Toposens 3D ultrasonic sensing technology for 3D collision avoidance. It enables customers to use pre-filtered point clouds displayable in a Graphical User Interface (GUI) to make use of the 3D collision avoidance functionality by setting dynamical three-dimensional, adjustable warning- and stopping-zones.

Is your AGV accident and deadlock prone because its existing sensor system struggles to detect transparent or complex objects such as forklift forks, or even small objects lying in the path of the AGV?

Most optical-based sensor solutions can struggle with detecting certain colours (such as black-coloured forklift forks) and have difficulties working under certain weather and lighting conditions (dark surroundings, fog or reflecting surfaces, for instance). Based on sound, the ultrasonic sensor technology at the heart of ECHO ONE® is typically tolerant to lighting and weather conditions. Thus, it can detect complex items such as the tip of a forklift fork, transparent surfaces or tiny objects lying in the path of your AGV. This reduces the occurrence of potential accidents and ensures a smooth workflow.

Does your mobile robot perform in-efficiently in the external environment due to dirt, dust, bad weather – or bad lighting conditions?

With a housing built to IP67 certification, the ECHO ONE® is robust to dirt, dust, and water. Also, unfavourable lighting conditions or specific colors, such as black, do not compromise the sensor’s detection capabilities. This is due to the physics of the sensor which operates with ultrasonic technology. This helps your mobile robot perform efficiently in any industrial work environment, even outdoors on a bad day.

Do you find that you have to integrate several sensors to be able to cover a large enough detection area, adding to your surplus costs?

The ECHO ONE® can detect multiple objects located in a substantial detection area around a mobile robot. This is achieved through the sensor’s huge opening angle, boosting a horizontal and vertical Field-of-View (FoV) of up to a whopping 180° at ultra-short-range (from 100mm) and up to 110° at 3m (horizontal FoV).

On a standard sized AGV or AMR, one ECHO ONE® will thus be enough to cover the whole area in front of it, and likewise at the back to give you a full 360° view.

Does your mobile robot struggle to detect objects in ultra-close range within its immediate environment?

The ECHO ONE® operates with a minimal blind zone, being able to detect objects from as close as 100mm. This takes robot safety to the next level and improves your AGV’s or AMR’s performance. Being able to detect objects in ultra-close range to a mobile robot is crucial to a 3D collision avoidance.

1. Improve operational efficiency

Traditional 1D Time-of-Flight sensors can detect only the closest object relative to the sensor. Due to our unique hardware setup and advanced algorithms-based software technology, our sensor can detect multiple objects in 3D space in real-time. This reduces accidents, optimizes your factory workflow, and improves your operational efficiency.

2. Ease the hassle of set-up and integration

Our unique integration platform offers you great flexibility to evaluate the ECHO ONE® in your individual application. It consists of a:

- Software package, which include ROS, Toposens Sensor Library, Firmware Update Tool and Toposens 3D Visualizer

- CAN communication interface

3. Reduce costly accidents by detecting even the most complex objects in 3D space

Most optical-based sensor solutions can struggle with detecting certain colours (such as black-coloured forklift forks) and have difficulties working under certain weather and lighting conditions (dark surroundings, fog or reflecting surfaces, for instance). Due to being sound-based, the ultrasonic sensor technology at the heart of ECHO ONE® is typically tolerant to lighting and weather conditions. Thus, it can detect complex items such as the tip of a forklift fork, transparent surfaces or tiny objects lying in the path of your AGV. This reduces the occurance of potential accidents and ensures a smooth workflow.

4. Use your AGV safely in any environment

As the IP67 certification reflects, the ECHO ONE® is robust to dirt, dust, and water. Also, lighting conditions or specific colors do not interfere with the sensor’s capabilities as our sensor operates with ultrasonic technology.

5. Safe costs by using just one sensor with enhanced perception abilities

The ECHO ONE® is able to detect multiple objects in front and at the sides of it. This is achived through the sensor’s very large opening angle, boosting a horizontal and vertical Field-of-View (FoV) of up to 180° at ultra-short-range (from 100mm) and up to 110° at 3m (horizontal FoV).

Thus, one ECHO ONE® sensor will be enough to cover the whole area in front of your AGV.

6. Improve AGV operational performance with a reduced blind zone

The ECHO ONE® operates with a minimal blind zone, being able to detect objects from as close as 100mm. This takes robot safety to the next level and improves your AGV’s or AMR’s performance. Being able to detect objects in ultra-close range to a mobile robot is crucial to a 3D collision avoidance.

Operating Modes

3D Collision Avoidance

Stand Alone

3D Collision Avoidance

Sensor Fusion

In stand alone mode, the sensor system signals zone

violations via digital IOs or Ethernet

In sensor fusion mode, the pre-processed point cloud can be

accessed via ethernet.

The easy-to-use plug and play solution for next-level robotic safety.

Technology

GATEWAY: The TPU acts as a gateway between Toposens 3D Ultrasonic Sensors and customer applications.

FILTERS: It features a set of sophisticated filters to pre-filter the point cloud obtained by the ECHO ONE®

3D COLLISION AVOIDANCE: 3D Collision avoidance is adjustable via configurable warning zones and stopping zones in easy-to-use graphical interface (GUI).

Graphical User Interface

The easy-to-use graphical user interface (GUI) visualizes the adjustable warning zones and stopping zones, which are configurable depending on your use case.

Individual parameters can also be adjusted in the GUI together with the sensor vehicle positioning.

Application

Mobile Robot

Collision Avoidance

Reduce costly accidents & deadlocks, and increase warehouse productivity with our Toposens ECHO ONE®

AGV Collision

Avoidance

Reduce costly accidents & deadlocks, and increase warehouse productivity with our ECHO ONE®

Autonomous

Parking

Reduce accidents and improve parking procedures with our 3D ultrasonic sensors for autonomous parking

Other

Use-Cases

Get in touch with us to discuss your individual requirements.

Ready to Order?