ECHO ONE DK

Evaluate our turn-key solution in your application

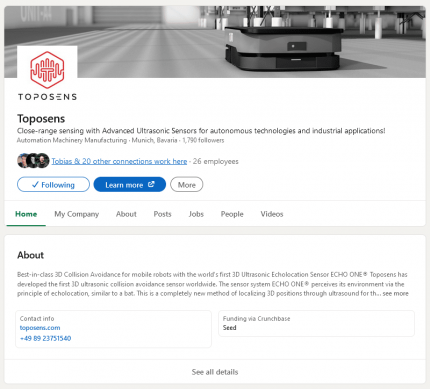

ECHO ONE® Development Kit

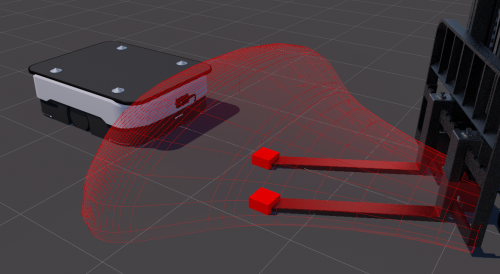

The Toposens ECHO ONE® Development Kit (ECHO ONE® DK) plus Toposens Processing Unit Development Kit (TPU DK) enables you to fully evaluate and integrate our 3D Collision Avoidance system in your individual application first before making it an integral part of your operational processes.

It enables you to demonstrate and validate the functionality and performance of our 3D Collision Avoidance System including its high accuracy, ultra-wide opening angle and small blind zone.

ECHO ONE DK

TPU DK

AGV 3D COLLISION AVOIDANCE

Technical Specifications - Overview:

ECHO ONE Development Kit

CAN

Communication Interface

from 200 mm

Operating Range

~20Hz

Frame Rate

up to 180°

Opening Angle

IP67

Certified

ROS

Package

Toposens Processing Unit Development Kit

ETHERNET

Communication Interface

6x

Digital Inputs

3 x NO Contacts

Relays Outputs

< 5 W

Low Power Consumption

9 - 30 V

Wide Voltage Range

User-friendly GUI

Configuration Interface

Easy Integration

Our development kit platform gives you great flexibility to evaluate our sensor in your individual application:

CAN as a communication interface

A separate Interface Adapter

(USB adapter + Micro USB Cable) to connect the ECHO ONE DK to your PC.

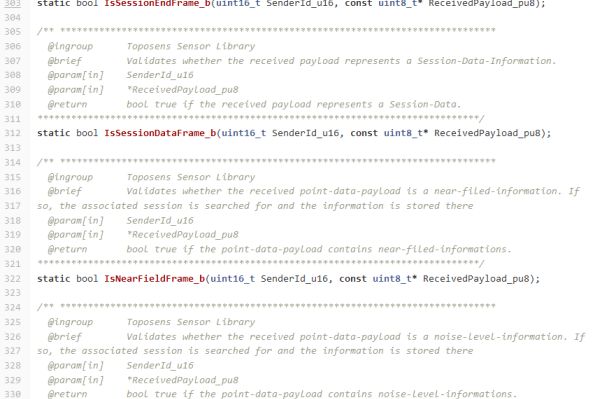

Toposens Sensor Library for convenient implementation of the ECHO ONE DK sensor into customer projects.

Firmware Update Tool via Interface Adapter to update the ECHO ONE DK’s firmware.

Use Cases

AGV Collision

Avoidance

Reduce costly accidents & deadlocks, and increase warehouse productivity with our ECHO ONE DK.

Autonomous

Parking

Reduce accidents and improve parking procedures with our 3D ultrasonic sensors for autonomous parking.

Passenger

Detection

Prevent in-cabin accidents with our proprietory 3D ultrasonic passenger detection technology.

Presence

Detection

Detect and track people as well as moving objects in scenarios like stopping elevator doors.

Our Customers